|

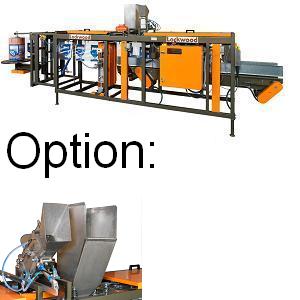

Horizontal filling- and closing machine for PE-film bags. This PLC-controlled machine is easily to operate and is suitable for packagings from 0,5 - 10 kg in prefabricated PE-film, with separation knife. Horizontal filling- and closing machine for PE-film bags. This PLC-controlled machine is easily to operate and is suitable for packagings from 0,5 - 10 kg in prefabricated PE-film, with separation knife.

The Lockseal HS has an undisturbed transit through the special open/close filling opening with vibrating hopper. Combined with the self-adapting Lockwood zebra sealsystem, this means an undisturbed transit of potatoes, onions, carrots, sprouts and numerous of other products.

The Lockseal HS with the Lockwood weighing machines make the best combination but it also can be used in combination with other current weighing machines.

Operation:

The poly is fed through the machine with the help of special V-belts. Control signals in the transport indicate the right moment for stopping, perforating and sealing. In this way the filmbag is correctly positioned underneath the filling opening and the bag can be filled. The support belt carries the bags filled to the horizontal sealer, where the bag is closed and goes to the end of the filling/closing machine.

Options:

Option double filling hole and tilting bucket.

Option possibility for 25 kg bags.

Electric supply:

3,5 kW, 400 V with Neutral and Earth, 50Hz.

3,5 kW, 240 V with Earth, 60Hz.

Weight:

Appr. 700 kg.

Conditioned air supply:

6 bar, appr. 125 l/min.

Packaging:

PE-film 30 bags/min., depending on product and film quality.

More options:

- Increased height or moveable.

- Also available in left-handed version.

- Vertical sealing device or separation knife.

- Double horizontal sealing with handgrip perforation.

- Bag closing with tapesealer, staples or kwik-lok.

- Coding/labeling machine.

- Ionization bar.

- Bag separator device.

- Modifications for apples.

- Also in 10 kg packagings version.

|